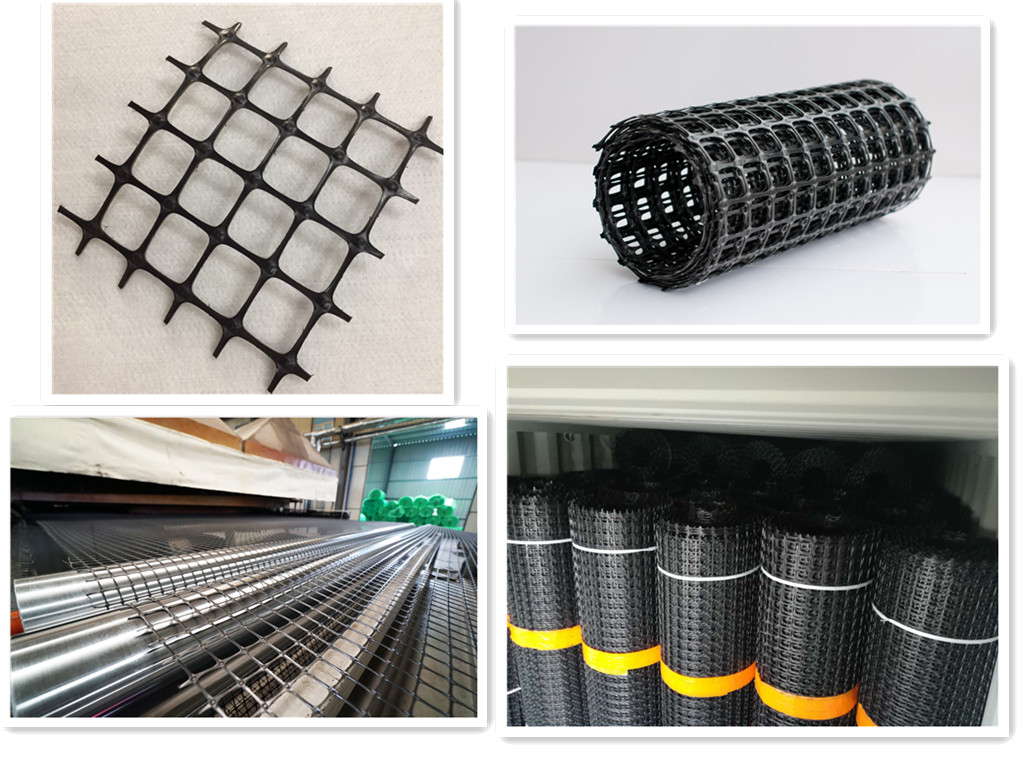

Product: Biaxial Plastic Geogrid

Material: Plastic

longitudinally to submit the elongation ratio:≤16%

Crosswise submits the elongation ratio:≤13%

Features:High tension resistance

The plastic two-way geogrid is made of high-molecular polymer through extruding, forming and punching process, and then stretched vertically and horizontally. The material has great tensile strength in the longitudinal and transverse directions. This structure can also provide an ideal chain system for more effective force bearing and diffusion in the soil, suitable for large-area permanent bearing foundation.

PP Bi-axial Geogrid for Road (ground) Base Description:

PP Bi-axial Geogrid is manufactured from Polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

PP Bi-axial Geogrid for Road (ground) Base Features:

1. High tension resistance, high plane torsion resistance modulus, good creep resistance and stable

Chemical nature.

2. High mechanic damage resistance and durability and large friction factor with sandy stone.

3. It can improve bearing force of foundation (normal improvement of above 40%) and increase diffusion angle(average increase to 50 degrees from 38 degrees).

4. Under the function of shaft times with same load, it can decrease 30%-40% of filling thickness for reaching same effect, when technical grid reinforcement is used, road bed with same thickness can bear more 3-5 times.

PP Bi-axial Geogrid for Road (ground) Base Application:

1.Reinforcement of road beds of various highways, railways and airports.

2.Reinforcement of permanent bearing road beds of large parking area and dock goods yard.

3. Slope protection and culvert reinforcement of railway and highway.

4. Secondary reinforcement of soil slope after uni-axial tension technical grid reinforcement

and further reinforcement of soil slope so as to avoid soil erosion.

5.Reinforcement of mile and gallery.