Geomembrane is a kind of waterproof barrier material with high quality polyethylene primary resin as the basic raw material.

Mainly products are HDPE Geomembrane, PVC Geomembrane, LDPE Geomembrane, EVA Geomembrane etc.

1. Complete width and thickness specifications.

2. Has excellent resistance to environmental stress cracking performance and excellent resistance to chemical corrosion.

3. Excellent chemical resistance.

4. Has a larger operating temperature range and a longer service life.

5. Used in landfills, tailings storage sites, channel seepage prevention, dyke seepage prevention and subway engineering, etc.

HDPE geomembrane (also known as impermeable film).its thickness of 0.2-3mm,the thickness of 0.8mm above also known as waterproof plate.It is a kind of waterproof barrier material with high quality polyethylene primary resin as the basic raw material.The main component is 97.5% high density polyethylene and about 2.5% carbon black.

PVC geomembrane is PVC waterproof,it is a kind of high quality polymer waterproof board,Through the addition of plasticizer,anti-ultraviolet agent,anti-aging agent stabilizer and other processing AIDS in PVC resin,the polymer waterproof rolling material is produced by extrusion method.Thickness:0.8mm-2.0mm.Roil length:20m or customizable.Color:black or according to your request.Life span:up to 50 years.

EVA geomembrane is one of the geomembrane series products. EVA is ethylene-vinyl acetate copolymer. It has good flexibility, flexibility, elasticity, weather resistance, environmental stress crack resistance and adhesion performance. Higher than ordinary polyethylene, because it has strong flexibility at the same time, it is very convenient in construction and the welding effect is very good.

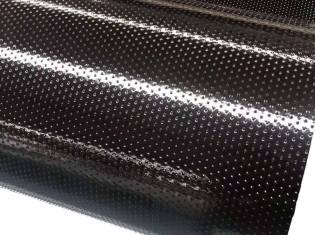

As impermeable substrate, rough geofilm is a kind of impermeable geofilm which is made by roughening resin raw material through roller extrusion or blown membrane and processed by special process formula. The performance of the new material geofilm is mainly to isolate and prevent seepage.

At present, the main application of geomembrane anti-seepage, with polyvinyl chloride (PVC) and polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), tunnel in the application and design using the ECB (ethylene vinyl acetate modified asphalt blending geomembrane), they are a kind of high polymer chemistry flexible material, the proportion of small, extensibility, adapt to the deformation capacity, high corrosion resistance, good low temperature resistance, frost resistance performance is good.

Single rough surface and double rough surface geofilm can increase the friction coefficient with contact surface, enhance the anti-slip function of geofilm, especially suitable for slope, steep slope and vertical anti-seepage, and improve the stability of the project.

Composite geomembrane is divided into one cloth one film, two cloth one film, multi-cloth multiple film, width 4-6m, weight of 200-1500 g/ m2, high tensile, tear resistance, bursting and other physical and mechanical performance indicators, the product has high strength, good extension performance, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, seepage resistance and other characteristics.

It can be used in unconventional temperature environment because of its high polymer material and anti-aging agent added in the production process.

It is often used for anti-seepage treatment of dykes, drainage ditches and anti-pollution treatment of waste sites.