Back to List

Back to List

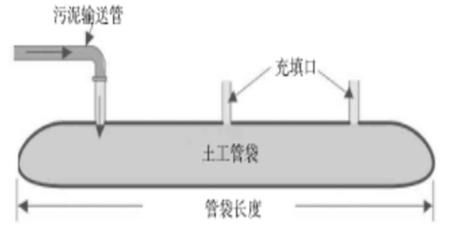

Geotechnical pipe bag or a large-scale pipe bag and inclusion made of high-strength geotextile, its diameter can be changed according to needs, and the length has exceeded tens of meters. Geotechnical pipe bags were originally used in dike engineering. At present, through the efforts of technical workers, they have been applied to environmental protection, agriculture and other fields. With the deepening of people's research, their application fields will become more and more extensive

The material of geotechnical pipe bag is generally made of high-toughness polypropylene, generally black; according to different specifications of products, adjust the commonly used material 400g/㎡; the length is not limited, the width can be multi-spliced and the width is not limited, but it directly affects the wider the strength of the material The higher the material strength is required; the filling height is basically set to two-thirds of the diameter of the pipe bag; it can be customized according to the diameter of the grouting machine on the site, and the agent can be added according to the actual situation (increasing the solidification speed to accelerate the separation of mud and water)

Comparison of dredging products

1. The traditional natural dewatering method of the mud yard: This method has simple technology and a large area for the disposal of river bottom sludge. It is a common method for domestic bottom sludge treatment projects (including the cleaning and treatment of Taihe river bottom sludge). However, the efficiency of this dehydration method is very low, and this method of using a storage yard to treat contaminated bottom sludge still has certain environmental and safety hazards. Since the bottom mud in the storage yard is exposed and is in direct contact with the surrounding environment, if the remaining water treatment in the storage yard does not meet the standard, it will cause secondary pollution to the surrounding water body.

2. Mechanical dewatering method: to deal with organic pollution and heavy metal contaminated bottom sludge. Although the dewatering effect is good, there are high one-time equipment investment, consumption of power and energy, construction of workshops and workshops, and the processing capacity cannot meet the short construction period of river reservoir bottom sludge treatment. Insufficient requirements.

3. Geotechnical pipe bag dredging: Convenience: The diameter and length of the geotechnical pipe bag can be adjusted as required, with strong plasticity, stackable, and convenient transportation. Environmental protection: fully enclosed construction, almost no noise, not easy to cause secondary pollution. High efficiency: It can fully meet the treatment capacity of wastewater and sludge. The treatment capacity can be increased or decreased according to the flow rate of the pump. The volume reduction effect is good: the sludge volume can be basically reduced by more than 90% within one month, which makes the subsequent removal and treatment easier. Wide application: Both large and small wastewater treatment projects and sludge dewatering projects can be used.

Construction method of geotechnical pipe bag:

The first step is filling, using high-strength and permeable geotextiles to make the actual bag body, and then filling the mud into the bag body.

The second step is drainage. Because the geotextile forming the bag body has small holes, it can retain the solids in the mud and drain the water out of the mud. This can effectively reduce the volume of the contents in the bag and the bag can be filled repeatedly , Until it reaches the allowable height of the bag material, and the discharged water can be reused.

The third step is consolidation. After multiple filling and drainage, the fine particles left in the bag will gradually be consolidated due to the drying effect.

Technical advantages of dredging pipe bag

(1) The volume of the filter bag can be adjusted arbitrarily, with a large range and flexible engineering processing capacity;

(2) No need to invest in dehydration machinery and equipment, no electric power configuration, no need to move;

(3) The filter bag system has low investment, very little manpower and simple operation;

(4) The filter bag can be placed in any suitable place near the river and lake, and the drainage can be directly flowed into the river and lake with clear water;

(5) The filter bag can be placed at multiple points according to the operation of the dredging vessel, which is suitable for in-situ dehydration of silt;

(6) The sludge is a closed operation during the dehydration process, which can avoid secondary pollution;

(7) The moisture content of the sludge in the bag can be adjusted according to the number of filling times, pressure and idle time of the filter bag;

(8) Special filter cloth is used, with good filtering performance, high strength and not easy to age;

(9) The formula of the medicament can be adjusted according to the condition of the sludge to achieve the harmless treatment of the sludge;

(10) The dewatered silt can be used as slope protection soil for rivers and lakes or as soil for agriculture and greening;

(11) The system project has low investment, low operating cost and short construction period. Size selection