Back to List

Back to List

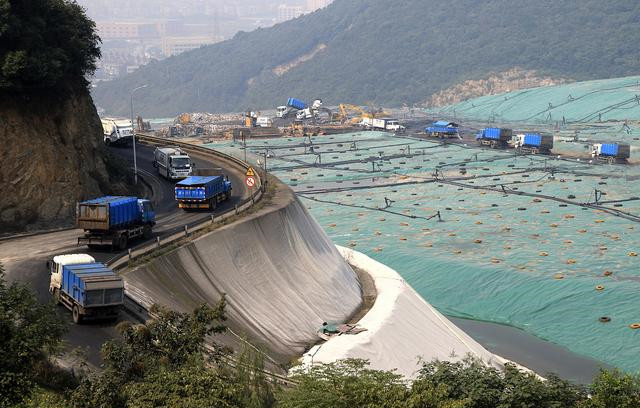

1.Storage, transportation and treatment of geotextiles

Geotextile rolls should be protected from damage prior to installation and deployment.

Geotextile rolls should be stacked in a place free of stagnant water, no more than four rolls high, and the marking page of the rolls can be seen.

Geotextile rolls must be covered with opaque material to prevent uv aging.

During stored procedures, the integrity of labels and data must be maintained.

Geotextile rolls must be protected from damage during transportation, including from the storage of materials to the workplace.

Geotextile rolls that have been physically damaged must be repaired.

Do not use badly worn geotextiles.

Any geotextiles that are exposed to leaking chemicals shall not be used in this project.

2. Laying method of geotextile

2.1 Manual rolling;

Cloth surface should be smooth, and there should be appropriate deformation margin.

2.2 Suture of geotextile: All sutures must be continuous (for example, no point suture is allowed).

Geotextiles must overlap at least 150mm before overlapping.

The minimum stitch distance from the cloth edge (the exposed edge of the material) shall be at least 25 mm.

Most geotextile seams consist of single seam chain stitch.

The thread used for suturing shall be a resin material with a minimum tension of more than 60N, and its chemical and uv resistance shall be equal to or exceed the geotextile.

Any "missing stitches" in the stitched geotextiles must be restitched where affected.

Appropriate measures must be taken after installation to prevent soil, particulate matter or foreign matter from entering the geotextile layer.

The cloth circle can be divided into natural circle,

3. Basic requirements for geotextile laying

3.1 The joint must intersect the diagonal line;

The distance of the horizontal seam must be greater than 1.5m where the balance with the foot of the slope or where stress may exist.

3.2 On the slope, anchor one end of the geotextile and then place the crimped material on the slope to ensure that the geotextile remains tight.

3.3 All geotextiles must be pressed with sandbags.

Sandbags will be used during the laying process and will remain until the layer above the material is laid.

4. Geotextile laying technology requirements

4.1 Base inspection: Check whether the base is smooth and firm.

If there are foreign bodies, they should be disposed of properly.

4.2 Test laying: determine the geotextile size according to the site conditions, and then try laying after cutting. The cutting size should be accurate.

4.3 Check whether the width of the salad is suitable and the seam should be flat and firm.

4.4 Positioning: Use a hot air gun to glue the overlapping parts of two geotextiles together.

The joints should be properly spaced.

4.5 When sewing overlapping parts, the stitches should be straight and smooth.

4.6 After stitching, check whether the geotextile is flat and defective.

4.7 If there is any unsatisfactory phenomenon, it shall be repaired in time.

5. Self-check and repair

5.1 All geotextiles and seams must be checked.

Defective geotextiles and seams must be clearly marked and repaired.

5.2 Worn geotextiles must be repaired by laying and heat-connecting small geotextiles at least 200 mm longer than the defect edge in all directions.

The thermal connections must be strictly controlled to ensure that patches and geotextiles are tightly bonded and do not damage the geotextiles.

5.3 Before laying each day, visually inspect all geotextile surfaces laid that day to ensure that all damaged areas have been marked and that repairs are carried out immediately to ensure that the surface is free of foreign matter (e.g. fine needles), nails and nails, etc. that may cause damage.

5.4 The repairing materials for holes or cracks shall be the same as geotextiles.

Patch 5.5 should extend to at least 30 cm of damaged geotextiles.

5.6 At the bottom of the landfill, if the geotextile cracks exceed 10% of the width of the coil, the damaged part must be removed and then the two geotextiles are joined together;

If the crack exceeds 10% of the coil width on the slope, remove the geotextile coil and replace it with a new coil.

5.7 The work shoes worn by the construction personnel and the construction equipment used shall not damage the geotextile.

Construction workers should not do anything on the laid geotextiles that might damage the geotextiles, such as smoking or poking the geotextiles with sharp tools.

5.8 For the safety of geotechnical materials, the packaging film should be opened before the geotextile is laid, i.e., one roll is laid and one roll is opened.

And check the appearance quality.

6. Matters needing attention for installation and construction of geotextile

6.1 Geotextile can only be cut with geotextile knife (hook knife).

If cutting is done on site, special protection measures must be taken for other materials to prevent unnecessary damage to geotextiles as a result of cutting;

6.2 During the laying of geotextile, care must be taken not to allow stones, large amounts of dust or moisture to damage the geotextile, block the drain pipe or filter or cause substances which may cause difficulties for subsequent connection of geotextile or underground geotextile;

6.3 After installation, visually inspect all geotextile surfaces to identify all damaged landowners, mark and repair them, and ensure that the laid surfaces are free of foreign matters, such as broken needles and other foreign matters, which may cause damage.

6.4 Geotextile connections shall comply with the following requirements: under normal circumstances, no horizontal connections shall be allowed on the slope except at the maintenance site (the connections shall not intersect the slope contour).

6.5 If seams are used, they must be made of the same or more geotextile materials and must be made of ultraviolet light resistant to chemical corrosion.

There should be a distinct color difference between the stitches and the geotextile for easy inspection.

6.7 Special care should be taken during installation to ensure that none of the gravel or gravel overlays in the soil enter the geotextile.

7. Damage and repair of geotextiles

7.1 When sewing, it is necessary to re-sew and repair, and ensure that the end of the skip part has been stitched.

7.2 In all areas except rock slopes, holes or cracks must be repaired and sewn with geotextiles of the same material.

7.3 At the bottom of the landfill, if the length of the crack exceeds 10% of the width of the coil, the damaged part must be removed and then the two parts of the geotextile joined together.