Back to List

Back to List

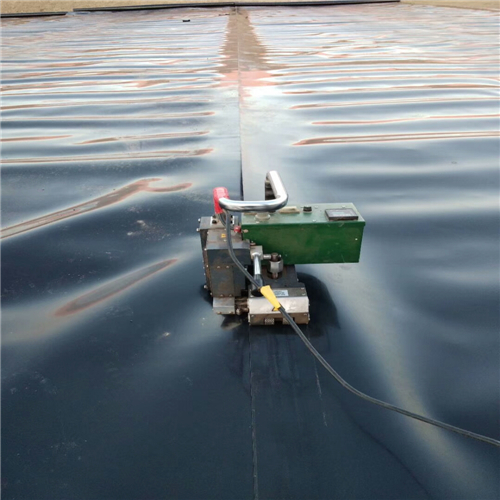

Geomembrane welding machine is one of many welding equipment. The main welding objects are: HDPE, PE-C, PP, LDPE. Grooved geomembrane, anti-seepage membrane; Mechatronics design, small size, light weight, on-site operation is very practical. Double welding seam lap welding, high temperature control accuracy, high welding strength, good sealing effect, the weld leaks in the middle of the weld, automatic crawling can realize automatic welding of slope, vertical and inverted.

Application:

Prevent leakage in landfills, waste liquid discharge tanks, public works, building foundation geomembrane, tunnel waterproofing, mine waterproof lining, reservoirs, irrigation ditches, embankment seepage membranes, breeding ponds, swimming pool linings, storage tanks, anti-seepage, chemical Reaction tank, sedimentation tank.

Welding Technology

1 Weld lap width: 80~100mm; the natural folds of the plane and the vertical plane are: 5%~8%; reserved stretch rate: 3%~5%; residue residue: 2%~5%.

2 The working temperature of hot melt welding is 280~300°C; the driving speed is 2~3m/min; the welding form is double welding.

3 Use manual extrusion welding gun as repair welding, repair damaged parts, and cut the same material. Types of geomembrane welding machine: double welding machine, single welding machine, hot wedge welding machine.