Back to List

Back to List

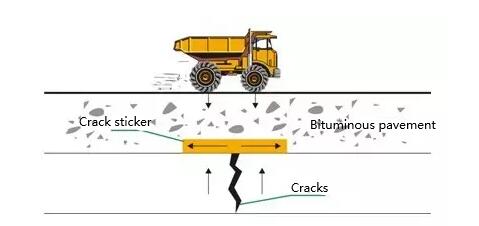

Water damage is one of the main reasons for pavement early damage of asphalt pavement crack stick at the grass-roots level of research and development and application greatly alleviated the disadvantages of pavement early water damage, especially to solve the problem of old and new pavement joint maintenance engineering played a good role, to improve the quality of continuous work of asphalt pavement and prolong the service life of pavement is of great significance.

1. The main function of basic anti-crack patch is to heal small puncture damage by itself, and to fill and heal small cracks automatically.

High tear strength, good durability, can effectively prevent the fracture expansion.

It can effectively prevent and prevent the occurrence and development of cracks at the base, and effectively treat radioactive cracks and bifurcation cracks.

The process is simple and will not pollute the environment.

Obvious economic benefits, less artificial input, no equipment input, good waterproof effect, due to its low temperature flexibility, adhesive bonding, bonding after the formation of permanent seamless adhesive layer, so that the rainwater can not enter the base cracks.

2. Analysis of anti-crack adhesion mechanism

The mechanical effect of anti-crack adhesive on asphalt pavement base indicates that polymer material, as a stress absorbing film, is a kind of flexible, tough and high elastic material, which can absorb the upward development of the strain stress on the base, thus delaying the reflection time of cracks to the pavement structure.

The anti-crack patch also has the locking bite effect, which can significantly improve the shear resistance and load transfer ability of the cracked section, and indirectly improve the strength and stability of the base layer.

Asphalt based polymer materials have good high and low temperature characteristics, which can make the material not significantly deformed and flow at high temperature, not brittle failure at low temperature, and keep the shape and mechanism of action unchanged.

3. Advantages of anti-crack patch

(1) Stress absorption and cracking resistance.

The polymer anti-crack sticking in the asphalt surface layer can disperse the pressure of the lower layer under the wheel contact and the stress of the area outside the wheel load edge, and form a buffer zone between the two stress areas, so as to gradually reduce the stress here and reduce the damage of stress concentration on the asphalt surface layer, thus effectively extending the life of the road.

(2) Overall stability.

Due to its good tensile strength and adhesion, the polymer anti-crack adhesive tape can connect both sides of the lower crack, forming an overall protective layer of 75 ~ 100mm wide.

(3) Good resistance to low temperature cracking.

Due to the polymer crack - resistant adhesive has a strong tensile strength.

Its application in asphalt base can improve the lateral tensile strength of base and resist large tensile stress without damage.

Even if a crack occurs in a local area, the stress concentration at the crack will disappear through the transmission of polymer anti-crack paste, and the crack will not develop to the surface layer and damage the road.

4. Anti-crack paste construction technology and operation steps

(1) According to the width of the crack at the base, select the specifications of anti-crack paste

(2) Crack treatment:

Cracks between 5 and 19mm in width must be cleaned and filled with sealant.

Cracks and depressions between 19 and 50mm wide should be filled with sand, sealant or asphalt mixture and compacting to the existing height.

Cracks or pits larger than 50mm in width must be cleaned and then filled with colloidal sand or hot asphalt mixture and compelled to the existing height.

It is necessary to level out cracks and depressions of different heights.

For the bridge deck, the road surface of the protuberance, must be cleaned or treated to the level.

(3) Peel off the isolation paper on the back of anti-crack paste and stick the anti-crack paste flat on the base layer with the crack as the center line.

(4) In case of irregular cracks, paper knife or scissors can be used to cut off the anti-crack paste, according to the direction of the crack tracking adhesive.

However, at the joint of anti-crack patch and anti-crack patch, an overlap of 50 ~ 60mm should be formed.

(5) Iron the anti-crack patch to the ground, and use small compaction equipment to compact, no bubbles, wrinkles and bulging phenomenon.

(6) Avoid the pollution and damage of the anti-crack adhesive surface after the construction of the base adhesive anti-crack adhesive plaster is completed.

5 Application Scope

6 the conclusion

Check the construction links, especially the mixture of paving, compaction, joint quality control to be meticulous.

Pay attention to the details of each process, details determine success or failure.

The application of waterproof paste and crack resistant paste is not only the result of attaching great importance to scientific and technological innovation and bold application of new materials, but also the concrete embodiment of the delicacy of maintenance construction.

At the same time, it is also a low carbon, environmental protection, green, construction method, can significantly reduce maintenance costs, save resources, save energy, reduce environmental pollution, is conducive to the sustainable development of highway maintenance.