HDPE geomembrane as a new type of material, has excellent anti-seepage, anti-corrosion performance, good chemical stability, and can be processed to meet the need of practical engineering features and functions, has been widely used in water conservancy projects such as seepage prevention of dam, dam, reservoir, as well as channels, reservoirs, sewage pool, swimming pool, housing construction, underground buildings, sites, environmental engineering, etc as proof, anticorrosion, leakproof, moistureproof material used. Developed countries from the 1930s, began to widely use this technology, Our country from the 1980s began to gradually promote the use of HDPE impermeable film in various projects.

Read More

LDPE geomembrane is a new geotechnical impermeable material which is mainly composed of polyethylene,ethylene,ethylene polymer and other materials.

Read More

PVC geomemes are PVC waterproofing sheets. It is a kind of high - quality polymer waterproof board. Through adding plasticizer, anti-ultraviolet agent, anti-aging agent, stabilizer and other processing AIDS in PVC resin, through the extrusion method to produce molding polymer waterproof rolling material. Composite PVC geotechnical film is composed of PVC board and geotechnical cloth. Roll joint has high tensile strength, high temperature resistance, low temperature resistance, good thermal performance and other advantages, can be used cold adhesion method or hot air welding method, so that the joint bond firmly, the overall waterproof layer closed tightly.

Read More

EVA geomembrane is one of the geomembrane series products. EVA is ethylene-vinyl acetate copolymer. It has good flexibility, flexibility, elasticity, weather resistance, environmental stress crack resistance and adhesion performance. Higher than ordinary polyethylene, because it has strong flexibility at the same time, it is very convenient in construction and the welding effect is very good.

Read More

As impermeable substrate, rough geofilm is a kind of impermeable geofilm which is made by roughening resin raw material through roller extrusion or blown membrane and processed by special process formula. The performance of the new material geofilm is mainly to isolate and prevent seepage. At present, the main application of geomembrane anti-seepage, with polyvinyl chloride (PVC) and polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), tunnel in the application and design using the ECB (ethylene vinyl acetate modified asphalt blending geomembrane), they are a kind of high polymer chemistry flexible material, the proportion of small, extensibility, adapt to the deformation capacity, high corrosion resistance, good low temperature resistance, frost resistance performance is good. Single rough surface and double rough surface geofilm can increase the friction coefficient with contact surface, enhance the anti-slip function of geofilm, especially suitable for slope, steep slope and vertical anti-seepage, and improve the stability of the project.

Read More

Composite geomembrane is divided into one cloth one film, two cloth one film, multi-cloth multiple film, width 4-6m, weight of 200-1500 g/ m2, high tensile, tear resistance, bursting and other physical and mechanical performance indicators, the product has high strength, good extension performance, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, seepage resistance and other characteristics. It can be used in unconventional temperature environment because of its high polymer material and anti-aging agent added in the production process. It is often used for anti-seepage treatment of dykes, drainage ditches and anti-pollution treatment of waste sites.

Read More

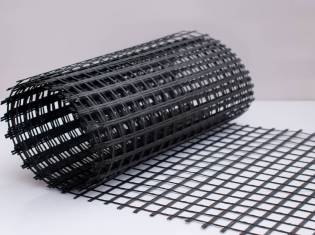

The Fiberglass Geogrid is made of Fiberglass. It is a net-like structural material made by a certain weaving process. To protect the glass fiber and improve the overall performance, it is a geocomposite material that has been processed by a special coating process.

Read More

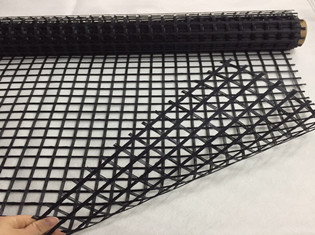

Warp-knitted polyester geogrid is a new type of high-quality geotechnical substrate that reinforces the roadbed. It uses high-strength polyester fiber or polypropylene fiber as the raw material and uses warp-knit directional structure. The warp and weft yarns in the fabric have no bending state and cross point.

Read More

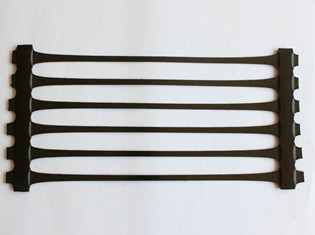

Unidirectional plastic technical grid is a kind of technical material with high strength that uses high molecular polymer as main raw material, adds certain ultraviolet proof and aging resistance agent and makes messy chain shape molecules have directional layout and from linear status by unidirectional extension.

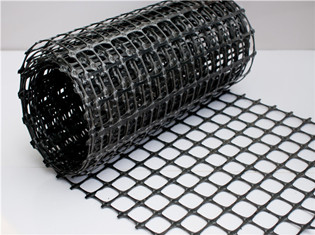

The plastic two-way geogrid is made of high-molecular polymer through extruding, forming and punching process, and then stretched vertically and horizontally. The material has great tensile strength in the longitudinal and transverse directions. This structure can also provide an ideal chain system for more effective force bearing and diffusion in the soil, suitable for large-area permanent bearing foundation.

Read More

Basalt geogrid is a kind of excellent geosynthetics for the cement concrete floor reinforcement, building reinforcement, road surface reinforcement and basement.

Warp-knitted composite geotextile is a new type of geotextile made of glass fiber (or synthetic fiber) as a reinforcing material and compounded with staple fiber needle-punched nonwoven fabric.

Read More

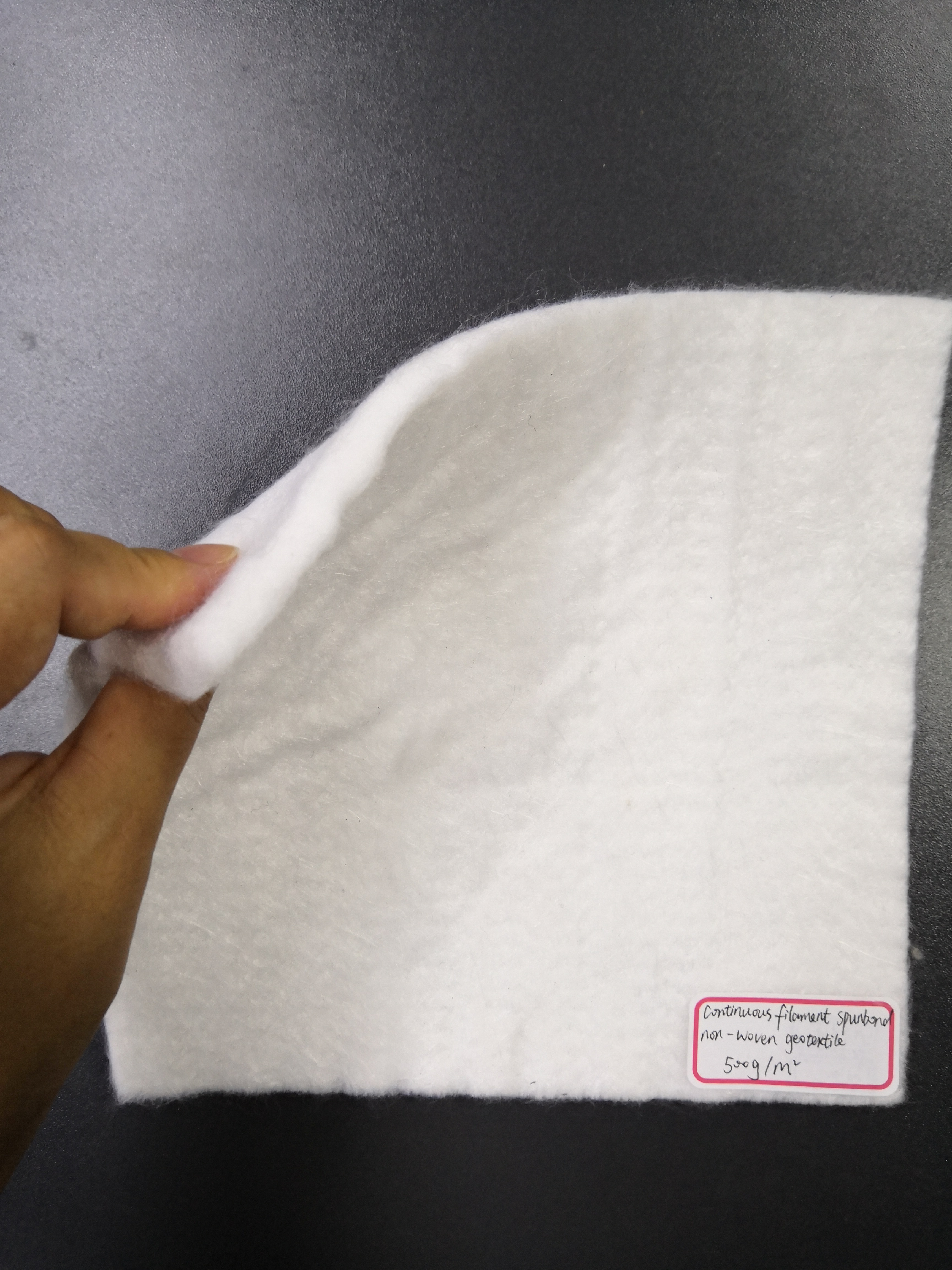

It replace the traditional engineering materials and construction methods, be safer to construction,and conducive to enviromental protection,can be more econimical, effective, lasting solution to the basic problems in engineering construction.

Read More

Anti-aging, Anti-acid and alkline, abrasion resistance, filtration, separation adn easy for construction

High strength PP Filament Woven Geotextile has excellent permeability, durability, widely use in railway, highway, sports hall etc.

High strength PET Filament Woven Geotextile has excellent permeability, durability, widely use in railway, highway, sports hall etc.

Drainage & Stabilization Woven Geotextile Fabric can be used to effectively filter all kinds of foundation soil. Laying a geofilter on the foundation soil can effectively filter the groundwater, thus ensuring the stability between the contact surface of the foundation soil and the drainage layer.

High Reinforced & Stabilization Woven Geotextile Fabric is woven with high-strength polypropylene (PP) wire drawing. With high strength and high durability. It is suitable for the reinforced engineering with strict requirements for long-term design life.

The Thermoplastice Polyolefin (TPO) waterproof membranes are the most popular waterproof materials in the world at present. It’s thermoplastic elastomeric waterproof materials by adopting advanced polymerization together with squeeze technology,which perform well in mechanical properties, high tensile strength,oxidation-resistance and resistance to puncture.

Read More

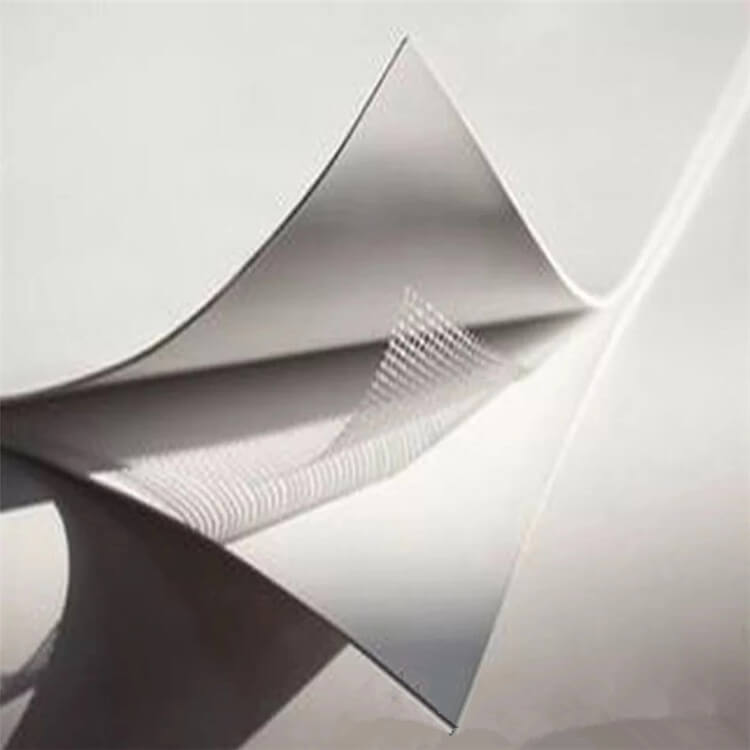

Thermoplastic polyolefin waterproofing membrane reinforced with polyester or fiberglass mesh in the middle of the membrane.

Read More

Geotexcon®️ is specially sewn from high-strength, high-molecular-weight polyester yarn. Acid and alkali resistance, abrasion resistance, crack resistance, high tensile strength, can be customized according to requirements

Read More

Shandong Hassan New Materials Co., Ltd., established in 2000 year, is one of the leading manufacturers in China’s new synthetic materials. Occupying 196,000 square meters, annual output of compound material is 80,000 tons. There are 450 employees, including 45 professionals. Factory has passed ISO9001/ISO14001/OHSAS18001 and CE certification. We own first-class production equipment, professional technical and sales team, responsible after-sale service.

Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible,Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible

2Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible,Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible

3Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible,Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible

4Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible,Multi workshop processing to ensure the customer's demand and complete the product order as soon as possible