Back to List

Back to List

1.1 Construction preparation

Organize and dispatch according to the construction entrants, construction machinery and equipment, high- and early-stage polypropylene geotechnical pipe bags, flat boats, and materials and materials that are not calculated by the construction organization, build temporary facilities, make preparations for the preliminary construction, and cooperate with the owner , To complete the relevant procedures of the construction to ensure that the construction starts smoothly as planned

1.2 Construction survey

First, re-measure and confirm the coordinate points, baselines and level points and data provided by the owner, and submit the re-measurement and confirmation opinions to the supervisor for review, set up a construction measurement control network, and after meeting the accuracy requirements, use the concrete package pile to reinforce the positioning , And protect the lead post. According to the determined construction survey control network (points), the dike axis is measured on the spot by the branch wire measurement method, and the vertical buoy (frame) method is used to mark the axis of the river, and the control elevation is measured.

1.3 Pipe bag laying

Before laying the geotechnical pipe bag, remove stones, sundries and other objects to ensure that the laying surface of the geotechnical pipe bag is flat and avoid damage to the bag body caused by the stress concentration at the sundries during the filling process. The processed bag is transported to the work site and laid according to the lofting position. In order to prevent the tube bag from rolling, slipping and displacement during filling, and to ensure the accurate position of the mud bag, the tube bag should be anchored and fixed after the tube bag is laid. The bottom pipe bag is anchored by laying anchor steel pipes on the outside of the pipe bag, and then using the anchor ring on the steel pipe and the steel pipe connection for anchoring. After the bottom pipe bag is filled, the upper geotechnical pipe bag has been filled with the bottom layer using the pull rings on both sides. The pull rings on both sides of the tube bag are tied together with geotechnical tape.

1.4 Tube bag filling

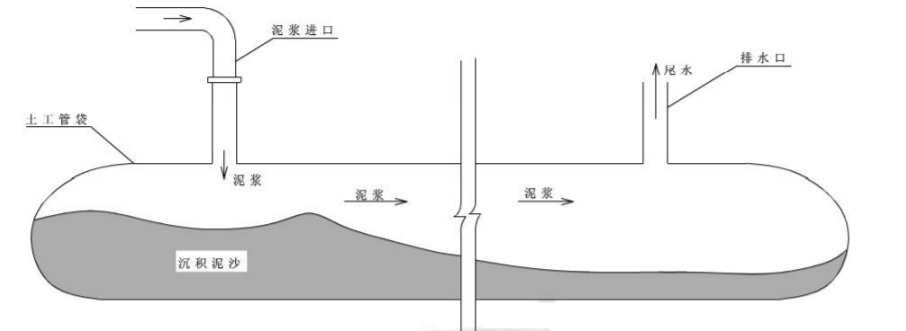

The high-toughness polypropylene geotechnical pipe bag is filled with a 22KW flush-suction mud pump unit. The mud pump unit is fixed on a flat boat. After the soil is sucked and sucked underwater, the mud pump mud pipe is led to the paved bag In the filling cuff of the body, the mud pipe is used for sand filling.

When filling the geotechnical pipe bag, the mud is poured into the cuff at one end at the earliest, and the pipe at the other end is drained, which is conducive to sedimentation and efficiency. During the filling process, it is necessary to check the mud and sand accumulation at the mud pipe mouth frequently, adjust the position of the mud pipe mouth in time, and constantly adjust the mud filling cuffs. During filling, manually step on the top surface of the bag body to make the soil particles rearrange and tighten. Make the sand filling in the bag even and full, ensure the filling is flat, speed up the drainage and consolidation speed of the bag body, when the entire sand bag reaches the screen slurry stage, appropriately reduce the filling sand bag machinery or stop filling to prevent the bag from bursting and leave a certain amount of consolidation Dehydration time.

During the filling process, the surveyor controls the top elevation of each layer of sand bag according to the cross-section drawing of the sand bag core. If the ideal height is not reached once during the filling process, after the sand bag is slightly consolidated, perform a second or more Fill up to the desired degree of filling. When filling, according to the capacity of each sand bag, determine the best mechanical equipment, so that each sand bag is filled in a tidal water and reaches the ideal filling height. After filling, the cuffs should be bound with geotechnical tape or rope (lead wire is not allowed). Once the sand-filled bag is damaged, it must be repaired with a needle immediately, and the stitch distance of the suture should not be greater than 5mm.

After the filling of each sand bag is completed, the construction team informs the surveyor and the quality staff to check and accept the top elevation and axis deviation of each layer of sand bags, and fill in the construction records. Those who are unqualified are not allowed to fill the upper layer of sand bags. Reconstruction is allowed after completion.

When filling the bag, the filling volume should be observed at any time, the filling tube should be removed when the requirements are met, and the filling construction record should be filled in. The construction inspection should be strengthened during the construction process, and the bag that does not meet the design requirements should be filled and inspected repeatedly until the entire bag meets the design requirements.

Schematic diagram of filling high tenacity polypropylene geotechnical pipe bag

2. Mechanical equipment configuration

The construction machinery and equipment of each tube bag filling operation team are equipped as follows: 4 sets of 22KW flushing and suction mud pump units, 1 100T flat ship, several steel pipes, and various quality inspection tools.

3. Quality Control

3.1 Establish a quality management system with the project manager as the first responsible person, unified command and hierarchical leadership, division and cooperation of various functional departments, strengthen the post responsibility system of personnel at all levels, and implement quality work in every process.

3.2 Strictly implement the quality "three-inspection system" for each process. After passing the self-inspection, report to the supervision engineer for acceptance. After the acceptance is passed, the construction task of the next process is carried out.

3.3 Strictly control the materials, conduct strict inspections on the materials carried out, and resolutely exit the unqualified materials.

3.4 During the construction process, pay more attention to the position control of the high-toughness polypropylene geotechnical pipe bags to ensure the smoothness and beauty of the embankment line and the firmness of the stack. During the filling process, special personnel shall be assigned to supervise on-site, always pay attention and take strict precautions. Overfilling and bursting of high-tough polypropylene geotechnical pipe bags ensured the quality and progress of the construction.