Back to List

Back to List

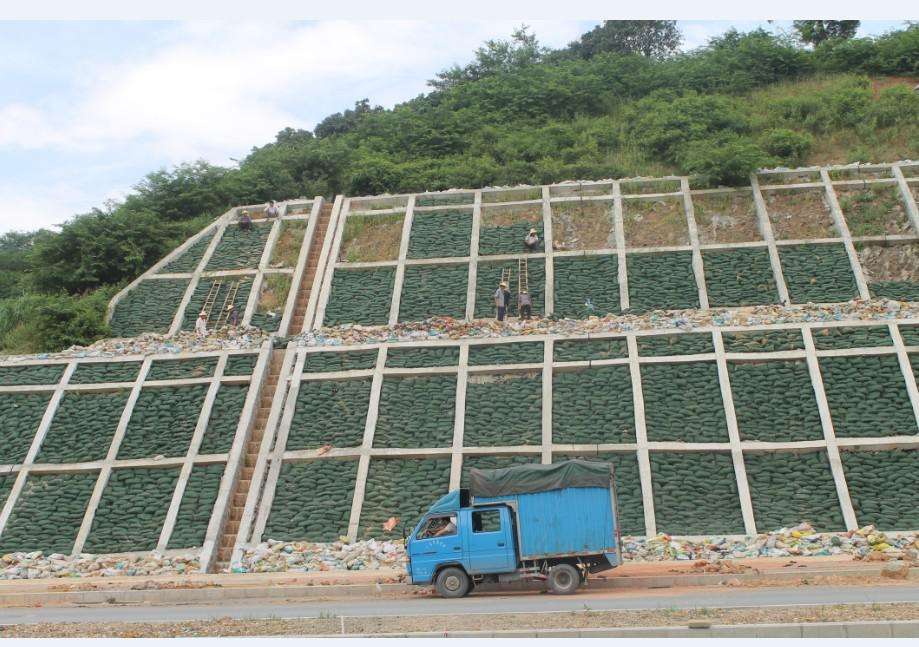

With the current deterioration of the ecological environment, many green plants have gradually become desertified. In order to protect the ecological environment and increase the coverage of green vegetation, many desert slopes have begun to use ecological bags to fix the nutrients of the water and soil, thereby planting trees and trees. Green engineering. The ecological bag is a permanent vegetation seeding module, which is easy for plant growth, and the product will never be degraded, and it can be 100% recyclable, which is very environmentally friendly.

Product performance:

1. Anti-moisture: The raw material of the eco-bag does not absorb water, and the bag will not be damaged when moisture appears, and the bag will not be deformed and is insoluble in polluted liquids (EPA Method 9090, US Environmental Agency).

2. Chemical resistance (PH): Extensive research and testing have shown that ecological bags have strong resistance to certain concentrations of acid and alkali chemicals, and can be used in most solid and heavily polluted places.

3. Resistant to biodegradation and animal damage: The eco-bag uses special formula materials, which do not support, absorb, or help the growth of fungi, do not rot, mold, or deteriorate. Eco bags will not be digested by insects and related animals, and will not become food for gnawing animals (rats), termites, borers, beetles, silverfish moths, etc.

4. Resistance to high temperature and low temperature: The eco-bag can withstand a high temperature of 150 degrees Celsius without melting, and can withstand a minimum temperature of -40 degrees Celsius.

Anti-ultraviolet (UV): The eco-bag contains carbon ink and other anti-UV ingredients.

The main purpose:

Mainly used in the construction of flexible ecological slopes. Eco-bag slope protection and greening is one of the important construction methods in barren hills, mine restoration, highway slope greening, river bank slope protection, and inland river improvement.

project

index

Plane size range

Can be customized according to design and engineering needs

Fabric weight range

≤110g, ≤125g, ≤150g (can be customized)

Tensile strength of fabric

≥4.5-12KN/m

Fabric elongation at break

40-70%

Volume calculation formula of ecological bag soil after forming

Degree = length of ecological bag-(12-15) cm, width = width of ecological bag + 0.7, high speed = height of ecological bag + 0.4

For example: a bag with an outer diameter of 810mm*430mm, the approximate size after filling, the length is 65cm, the height is 18cm, (the specifications of the ecological bag and the specifications of the forming after filling the soil can be designed according to actual requirements. The maximum allowable deviation is 8%)

Construction preparation:

1. Prepare in advance safety protection shovel, tape measure, compactor (tamping machine), broom, trolley/pattern, marking and other tools.

2. Clean up the construction site and avoid debris, tree roots and other debris. Consolidate the foundation to make the foundation tight enough to reduce wall settlement.

3. Build a designated stacking area to facilitate the stacking and bagging of materials.

Ecological bag construction process:

1. Packing and sealing bags: Packing bags at the construction site to minimize transportation and handling costs. Attention must be paid to ensure that the eco-bag is filled in accordance with the designed standard specifications and requires sufficient density.

2. Eco-bag installation: Place a connecting buckle in the bottom of the eco-bag so that it spans two eco-bags. The second layer repeats the same action for the entire wall and walks along the eco-bag, or compacts the eco-bag. The top of the bag helps to ensure that the ecological bags are securely interlocked. Straighten the bag from the front to the back so that the eco-bags are arranged one after another. After the bottom layer unit is placed, compact the eco-bag and backfill the back and front to prevent movement. If possible, install the entire length of the bottom layer before starting to stack up.

3. Eco-bag connection: Put the connecting buckle between the two bags on the top of the eco-bag, close to 1/3 of the inner edge, so that each connecting buckle spans two eco-bags. Shake the overlay on the eco-bag so that each connection buckle can penetrate the eco-bag. Interlocking is achieved by walking or compacting on the eco-bag to ensure good contact between the connecting buckle and the eco-bag.

4. Eco-bag stack: The upper stack will be placed on the previous layer, the surface sand bag is placed on the connecting buckle between the two sand bags in the lower layer, and the ecological bag will continue to be placed to compact the backfill. The weight from the upper layer will drive the connecting buckle barbs into the eco-bags, forming a strong connection between the eco-bags.

5. Eco-bag compaction: compacting the backfill is very important to the stability of the soil wall on the machine, so the backfill should be compacted to a minimum of 95%, and the backfill material must have proper humidity when compacted. To achieve the best results.

6. Install the reinforced retaining wall: cap the soil wall on the top of the wall, and place the long side of the eco-bag along the vertical wall to provide a reliable top. Cover the top of the wall with soil and ram it with a rammer to complete the final construction .

Because eco-bags can help green plants capture water and soil, absorb nutrients in the bag, and will not be affected by sandstorms, eco-bags are widely used on both sides of rivers, mines, sea and lake shores, and artificial Wetland, roof greening and other projects.